Digitizing is the science (and art, many would say), of collecting information about a physical object or space into a digital (computer-readable) format. At the most basic level, digitization is the documentation of information about a physical object.

The aspects of shape, dimension, movement and other characteristics provide a useful representation of an object for an intended purpose. This representation translates the characteristics of the object from the physical world to a virtual world, where each can be acted on and analyzed independently. A key consideration in the field of digitizing is that the quality of the translation will affect the results of subsequent work.

The concept of digitizing is known in modern engineering but is far from being well understood. Knowing the tools available, the conditions for their use, and how to properly stage and take a measurement with a high degree of accuracy is the cornerstone of the field of metrology. While you do not have to be a metrology expert to successfully digitize objects, it helps to know and apply the tools of the trade.

Tools for Digitizing

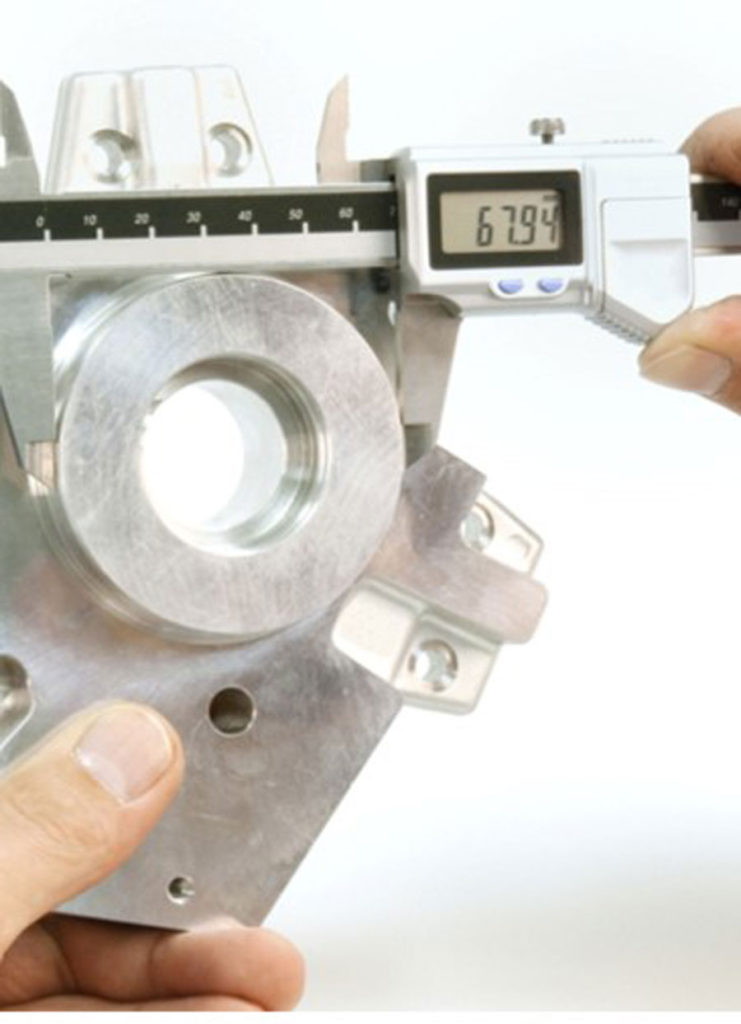

Different digitizing tools provide one or more physical dimensions. A caliper is a 1-dimensional tool capable of measuring linear dimensions and diameters with an accuracy of approximately +/-.001” (.025mm).

A pin gauge is a far more accurate measurement standard, but as a precision-machined cylinder, it can only be used for comparison if a feature is larger or smaller than its precision diameter. Most hand tools are one-dimensional (1D) digitizing devices and can be quite effective for accurately capturing single dimensions.

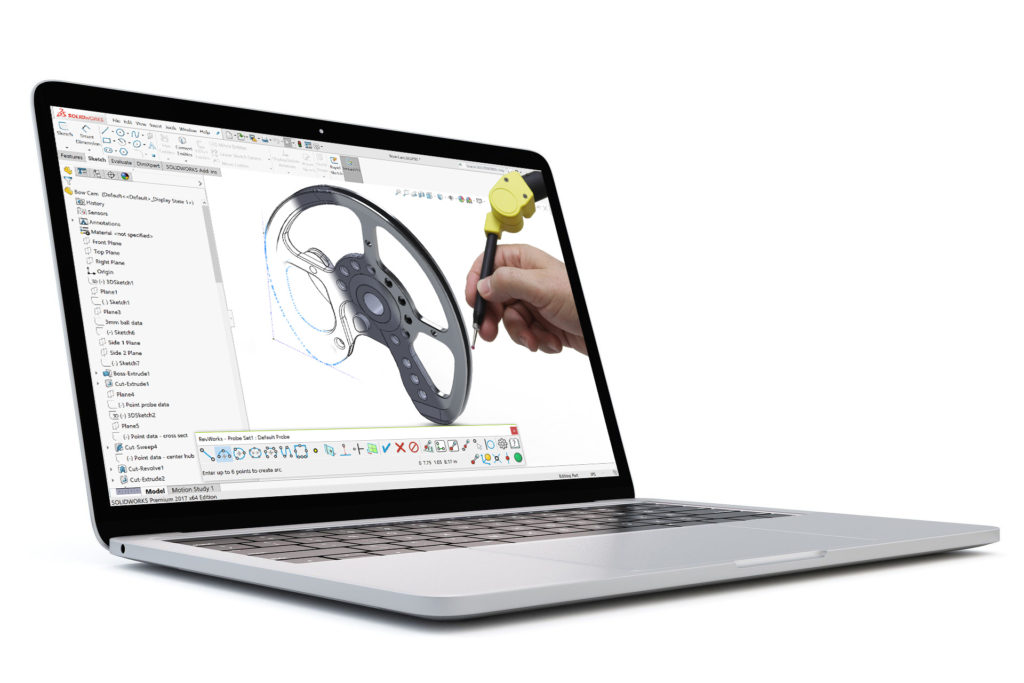

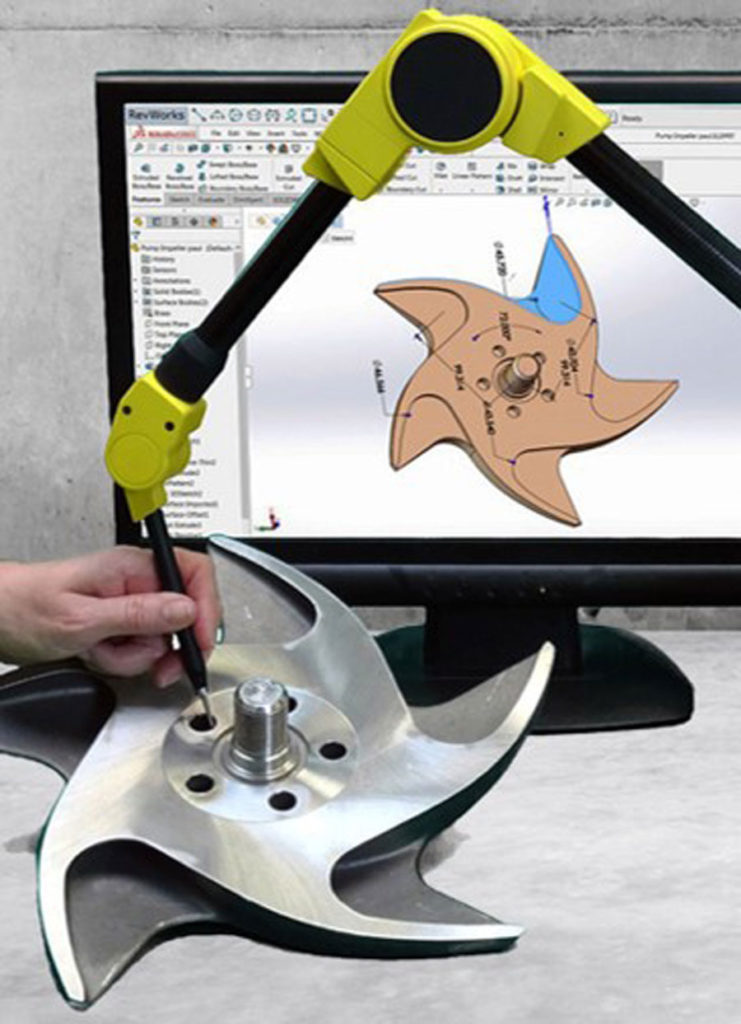

The power of modern multi-dimension digitizers is that all measurements taken are immediately related to each other. Unlike hand tools, digitizers are set up with a static relationship to the object being measured, and they establish a coordinate system relating all measurements to a common reference frame.

Two-dimensional (2D) digitizers are appropriate for working with drawings, patterns, or flat templates. Three-dimensional (3D) digitizers are used for capturing physical objects. Time is the fourth dimension and allows the capture of motion as well as position.

Types of 3D Digitizers

There are many types of 3D digitizers. For practical application purposes, they can be divided into two classifications: contact and non-contact. Contact digitizers accomplish their task by physically contacting the object being measured. Non-contact digitizers use other means to capture object surface data, such as structured light, line lasers, and more unconventional sensing technologies.

Non-contact digitizers typically capture thousands to millions of data samples in a very short period, known as high-density data. Contact digitizers, while having the capability of collecting high-density data, can also be used in applications where sparse, or low-density data, is preferred.

At the two ends of the data density spectrum, we can use different tools and techniques to reach similar documentation goals. For more information about digitizing and data density, read this article.

Copyright© 2021 Revware Inc. All rights reserved. Reuse and reprint allowed only with permission by Revware Inc., and with appropriate acknowledgments.

About Revware

Revware provides high, quality, simple to use, innovative, cost-effective modeling solutions to solve your design, metrology, and engineering problems.